Passive Fire Protection Test by Gerco-Fas

Objective – To determine the performance of Fire Walls with Penetration Seals

Overview

Here at Gerco-Fas we believe wherever possible that the testing of firestopping products is a vitally important part of our due diligence in predicting the fire performance of the products we provide within our projects.

For example, in the same way that the wheels of a commercial vehicle would not be tested as a standalone procedure in order to assess the performance of the entire vehicle, the same can be said for the fire performance of a passive fire protection product such as a cladding system. A cladding system’s success cannot be anticipated – founded on a fire safety check of any one component in isolation.

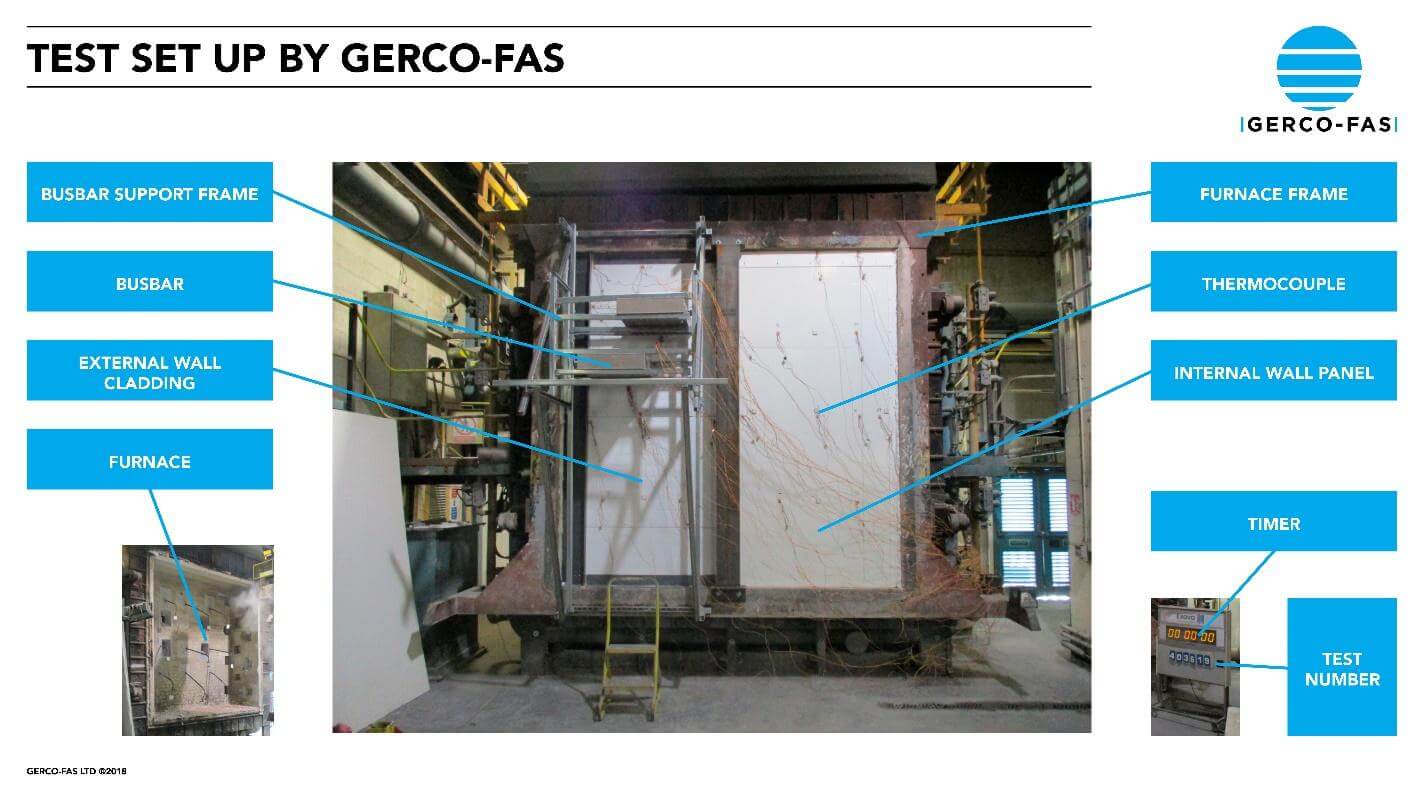

In reality the fire resistance performance of a system depends on the interaction of all the components working in concert, using the example pictured above we can identify several components, such as:

– Busbar Support Frame

– Busbar.

– External Wall Cladding.

– Internal Wall Panels.

– Firestopping material

– As well as fixings, fasteners and sealants.

Gerco-Fas Passive Fire Protection Fire Test

The company as a matter of course carries out periodic tests. This particular test is an excellent example displaying in detail what is involved to complete a passive fire protection product test.

We have provided a video covering the fire test as well as images which we hope you find informative.

Context

All Passive Fire Protection products that have a function to protect from fire require to be tested to ensure they are fit for purpose. This fire test carried out by Gerco-Fas explains the process in detail and includes an informative video of a live test.

Sometimes more than one particular product needs to interact and work together with other products in order to prove efficacy. For example, sprinklers and fire alarms, electromechanical door closures and fire alarms. Cavity barriers also act to compartmentalise space in ceiling and roof voids for instance.

More discerning clients are now asking questions on how differing wall constructions, when breached with services, will react as a whole when a fire occurs.

The way to put theory to the test is to build a construction which includes these elements and test them.

Pre-test

Gerco-Fas has carried out many such tests on behalf of clients and this is one of them. Inside a frame, different components are assembled and the frame is attached to a furnace. Testing is also carried out on structural fire protection such as intumescent coatings.

The furnace follows the standard time/temperature curve for buildings. An overpressure is also created in the furnace to mimic a real live fire. Thermocouples on the non fire side are attached to monitor the external temperature of the wall face. Any deflection of the wall is measured by a laser. Physical change is recorded by video.

Criteria for the Fire Test

The fire test laboratory chosen to carry out the test must be accredited. British, European, American and International fire resistance testing services is underpinned by UKAS accreditation to the internationally recognised testing laboratory standard ISO/IEC 17025. It is also a Notified Body Testing Laboratory (NBTL) under The Construction Products Regulation 16 Feb 2016.

Generally, with fire-stopping materials and the services passing through them, both insulation and integrity are required to pass to satisfy the standard and failure of either determines the test performance.

The test fails integrity when the heat 25mm from the non-fire side wall face ignites a cotton pad and fire breaches the wall allowing sustained flaming.

Should the temperature of specific thermocouples on the non-fire side exceed 180 degrees C + ambient temperature this is the point where insulation failure occurs. This is the temperature that can cause spontaneous combustion on the non-fire side.

In this particular case, the Passive Fire Protection Firestopping carried out by Gerco-Fas maintained its performance and failure occurred in a horizontal wall.

Fire Test Result

The test determined at just under 60 minutes when sustained flaming occurred on a horizontal wall panel joint. Other components maintained their integrity and insulation value.

The following image gallery shows the fire test sequence of events as follows:

1. Empty frame.

2. Frame fill up.

3. Fitting thermocouples.

4. Ready to commence fire test.

5. Control Room during live test.

6. Live screen showing test standard to be achieved.

7. Live test. Mid test product performing.

8. Fireside test termination.

9. Test terminated image at failure.

10. Fireside test termination.

11. Firestop performance review.

Firestopping by Gerco-Fas also acts as a seal to protect from smoke which therefore adapts well for use in Air Integrity Sealing, another discipline we carry out in addition to the following:

- Passive Fire Protection

- Structural Fire Protection

- Intumescent Coatings

- Cavity Barriers

- Air integrity Sealing

If you would like to discuss a new project, talk about a current one or find out more about our work, please contact Michael Anderson, Managing Director on 0845 862 7200 or email enquiries@gercofas.co.uk